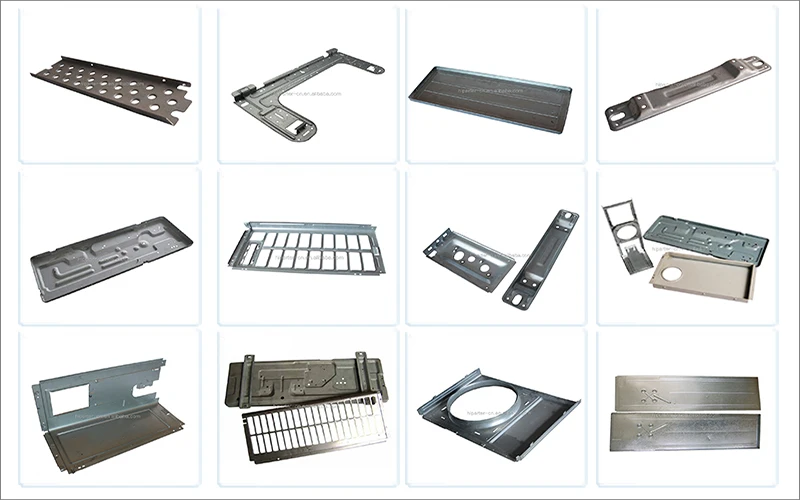

· In a single part can produce a variety of

geometric shapes

Household | Electronics |

Home Appliance | Automotive |

Retail | Medical |

Plumbing | Agriculture |

Food and Beverage | Construction |

Machinery | Quantity |

Grinding, Milling, Drilling machine | 8 |

CNC machine | 9 |

Fast speed wire cutting machine | 4 |

Middle speed wire cutting machine | 4 |

Low speed wire cutting machine | 3 |

Machinery | Quantity |

1600T Press machine | 1 |

800T Press machine | 1 |

400T Press machine | 2 |

200-250T Press machine | 4 |

110T Press machine | 7 |

45-80T Press machine | 3 |

630T Hydraulic machine | 1 |

315T Hydraulic machine | 4 |

200T Hydraulic machine | 1 |

Feeding machine | Quantity |

GO-600F Max material width 600mm Max material thickness 2.5mm | 3 |

NCBF-600 Max material width 600mm Max material thickness 4.5mm | 1 |

NCMF-700 Max material width 700mm Max material thickness 3.2mm | 1 |

LN4-800 Max material width 800mm Max material thickness 6.0mm | 1 |

Transaksi Anda di Cooig.com dilindungi dengan enkripsi SSL yang ketat dan protokol keamanan data PCI DSS.

Dapatkan pengembalian dana jika pesanan Anda tidak terkirim, hilang atau bermasalah.